Iko kushandiswa kwealuminium extrusion mukugadzirwa kwechigadzirwa uye kugadzira kwakawedzera zvakanyanya mumakumi emakore achangopfuura.Zvinoenderana neshumo ichangoburwa kubva kuTechnavio, pakati pa2019-2023 kukura kwemusika wepasi rose wealuminium extrusion kuchave kuchikwira neCompound Annual Growth Rate (CAGR) ingangoita 4%, heino rairo pfupi yekuti chii chinonzi aluminium extrusion, mabhenefiti. inopa, uye matanho anobatanidzwa mukuita extrusion.

Chii chinonzi Aluminium Extrusion?

Aluminium extrusion inzira iyo aruminiyamu alloy zvinhu inomanikidzwa kuburikidza nefa ine chaiyo yemuchinjikwa-chikamu chimiro.Gondohwe rine simba rinosunda aruminiyamu kuburikidza nefa uye rinobuda kubva paburi rekufa.Kana yadaro, inobuda muchimiro chakafanana nedhifi uye inodhonzwa kunze ichitevedza tafura yekumhanya.Padanho rakakosha, maitiro ealuminium extrusion ari nyore kunzwisisa.Simba rinoshandiswa rinogona kufananidzwa nesimba raunoshandisa pakusvina chubhu yemucheka wemazino neminwe yako.

Paunosvina, mushonga wemazino unobuda muchimiro chekuvhura kwechubhu.Kuvhura kwechubhu yemazino kunonyanya kushanda basa rakafanana nekufa kweextrusion.Sezvo kuvhura kwakasimba denderedzwa, mushonga wemazino uchabuda sehurefu hwakasimba extrusion.

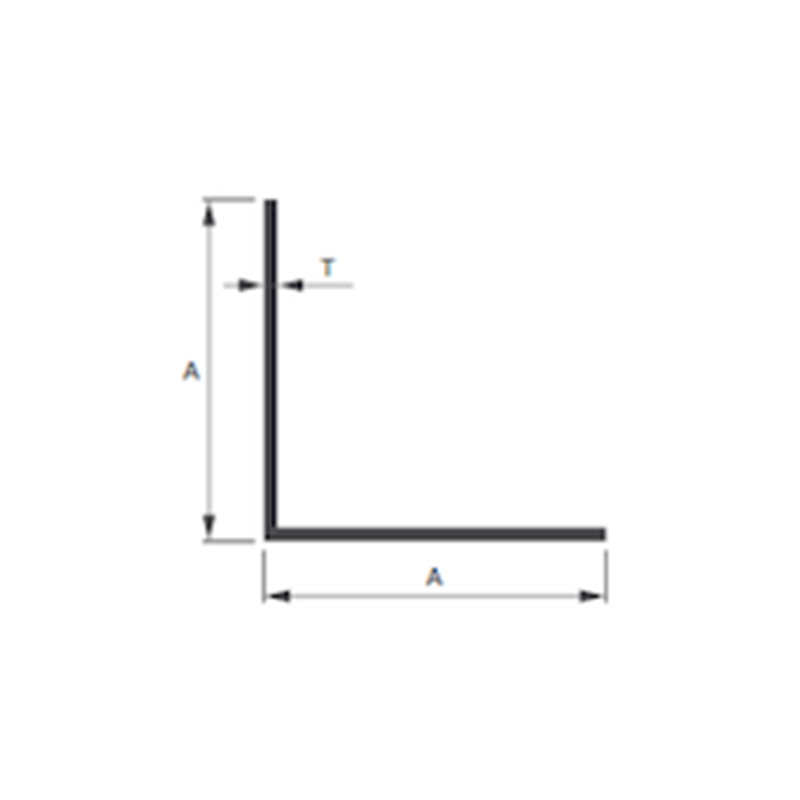

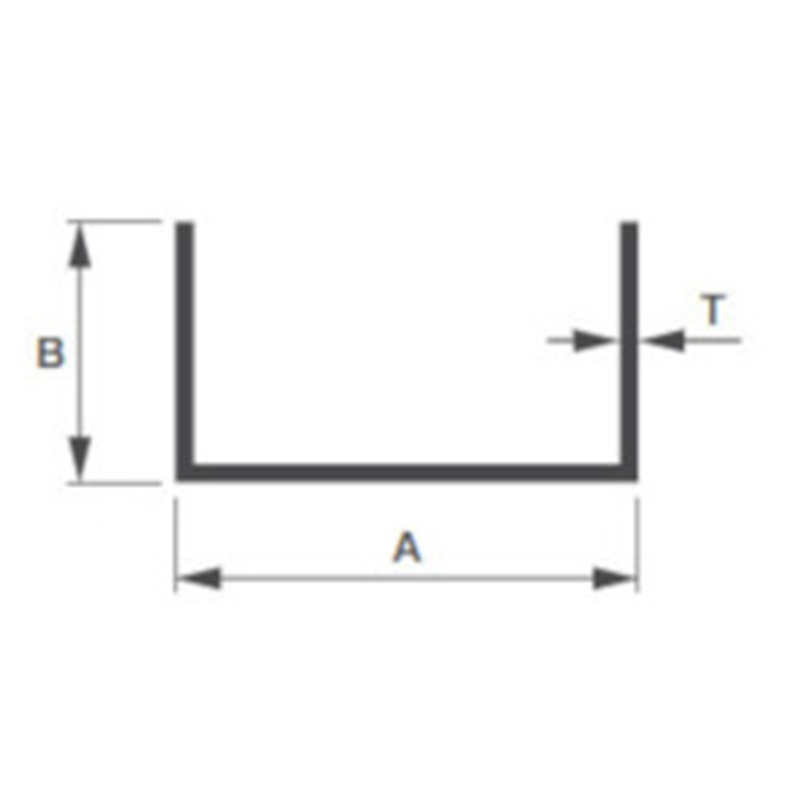

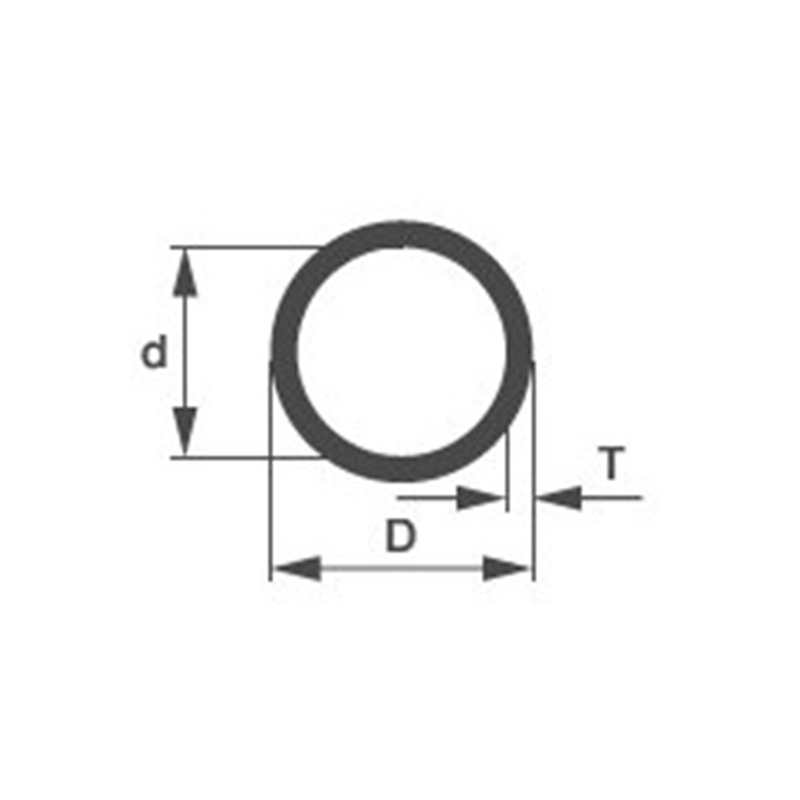

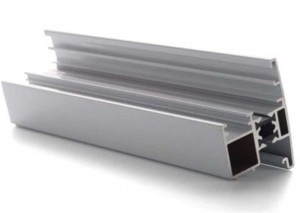

Heino mimwe mienzaniso yezvimiro zvinonyanya kuwedzeredzwa: makona, chiteshi, uye machubhu akatenderera.

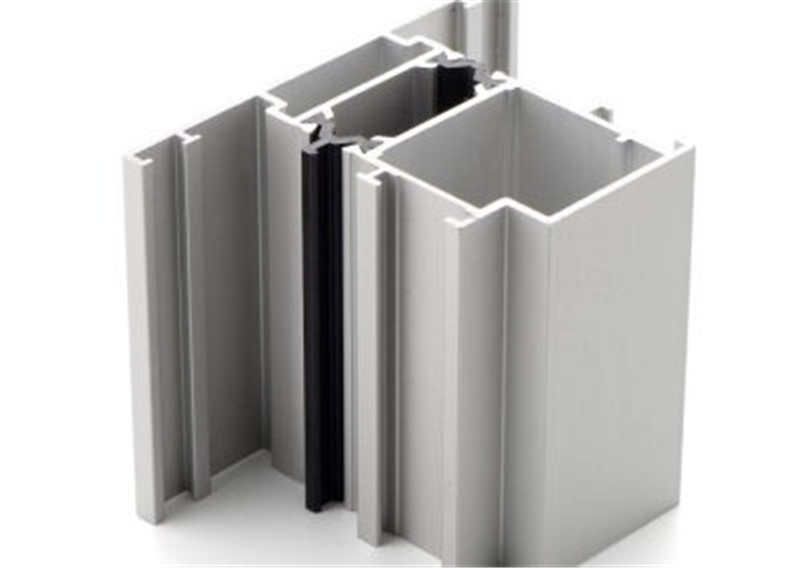

Kuruboshwe kune madhirowa anoshandiswa kugadzira madhiri uye kurudyi kune maratidziro ezvinenge zvapera aluminium profiles.

Kudhirowa: Aluminium Angle

Kudhirowa: Aluminium Channel

Kudhirowa: Round Tube

Kazhinji, kune matatu makuru mapoka e extruded shapes:

1. Yakasimba, isina maburi kana maburi akavharirwa (kureva danda, danda, kana kona).

2. Hollow, ine rimwe kana kupfuura voids (kureva sikweya kana rectangular chubhu)

3. Semi-hollow, ine chisara chakavharirwa zvishoma (kureva “C” chiteshi chine mukaha mudiki)

Extrusion ine zvisingaverengeke maapplication mumaindasitiri mazhinji akasiyana, anosanganisira ekuvaka, mota, zvemagetsi, aerospace, simba, uye mamwe maindasitiri.

Pazasi pane mimwe mienzaniso yezvimiro zvakaomarara zvakagadzirirwa indasitiri yezvivakwa.

Iyo Aluminium Extrusion Maitiro mune gumi Matanho

Nhanho #1: Iyo Extrusion Die Yakagadzirirwa uye Yakaendeswa kune Extrusion Press

Nhanho #2: An Aluminium Billet inopisa Isati Yawedzerwa

Nhanho #3: Iyo Billet Inoendeswa kune Extrusion Press

Nhanho #4: Ram Inosundira Billet Material mumudziyo

Nhanho #5: The Extruded Material Inobuda kuburikidza neDie

Nhanho #6: Extrusions inotungamirwa pamwe neiyo Runout Tafura uye Inodzimwa

Nhanho #7: Maextrusions akachekwa kuTafura Kureba

Nhanho #8: Extrusions yakatonhodzwa kuTembiricha yeKamuri

Nhanho #9: Maextrusions anofambiswa kuenda kuStretcher uye Akatambanudzwa muKurongeka

Nhanho #10: Extrusions Inofambiswa kune Yekupedzisa Saw uye Cheka Kureba

Kana extrusion yapera, maprofiles anogona kurapwa kupisa kuti awedzere zvivakwa zvavo.

Zvino, mushure mekurapwa kwekupisa, vanogona kugamuchira akasiyana epamusoro pekupedzisira kuti vawedzere chitarisiko chavo uye kudzivirira ngura.Vanogona zvakare kuita mabasa ekugadzira kuti vauye kune yavo yekupedzisira zviyero.

Kurapa Kupisa: Kuvandudza Mechanical Properties

Alloys mu2000, 6000, uye 7000 akatevedzana anogona kurapwa kupisa kuti awedzere simba ravo rekupedzisira rekusimba uye goho kushushikana.

Kuti uwane izvi zvinowedzera, maprofile anoiswa muovheni umo kuchembera kwavo kunokwidziridzwa uye vanounzwa kuT5 kana T6 tempers.

Zvinhu zvavo zvinoshanduka sei?Semuenzaniso, isina kubatwa 6061 aruminiyamu (T4) ine tensile simba re241 MPa (35000 psi).Heat-treated 6061 aruminiyamu (T6) ine simba rekusimba re310 MPa (45000 psi).

Izvo zvakakosha kuti mutengi anzwisise izvo zvinodikanwa zvesimba zvepurojekiti yavo kuti ave nechokwadi chesarudzo chaiyo yealloy uye hasha.

Mushure mekupisa kupisa, maprofiles anogonawo kupedzwa.

Kupedzisa Kwepamusoro: Kuvandudza Chitarisiko uye Kudzivirirwa kweCorrosion

Extrusions inogona kupedzwa uye yakagadzirwa nenzira dzakasiyana-siyana

Zvikonzero zviviri zvakakosha zvekufunga nezve izvi ndezvekuti ivo vanogona kusimudzira kutaridzika kwealuminium uye zvakare inogona kuwedzera kunaka kwayo.Asi kune zvimwewo zvakanakira.

Semuyenzaniso, maitiro eanodization anokobvuta simbi inongoitika-inoitika oxide layer, inonatsiridza kusaora kwayo uye zvakare kuita kuti simbi isanyanya kupfekwa, inonatsiridza kubuda kwepasi, nekupa nzvimbo ine porous inogona kugamuchira madhayi ane mavara akasiyana.

Mamwe maitiro ekupedzisa senge pendi, poda coating, sandblasting, uye sublimation (kugadzira chimiro chehuni), inogona kuitwa zvakare.

Mukuwedzera, pane zvakawanda zvekugadzira zvingasarudzwa zve extrusions.

Kugadzirwa: Kuwana Mamiriro Ekupedzisira

Sarudzo dzekugadzira dzinokutendera iwe kuti uwane zviyero zvekupedzisira zvauri kutsvaga mune yako extrusions.

Maprofayiri anogona kubaiwa, kudhiriwa, kuchekwa, kuchekwa, nezvimwe kuti zvienderane nezvaunoda.

Semuenzaniso, mafins ari extruded aluminium heatsinks anogona kuchinjika kugadzira pini dhizaini, kana screw maburi anogona kudhirwa kuita chidimbu chechimiro.

Zvisinei nezvinodiwa zvako, kune huwandu hwakasiyana hwekushanda hunogona kuitwa paaluminium profiles kugadzira iyo yakakwana yeprojekti yako.

Aluminium Extrusion Yakakosha Kugadzira Maitiro Kana iwe uchida kudzidza zvakawanda nezve maitiro ekugadzirisa chikamu chako dhizaini yeextrusion process, pls inzwa wakasununguka kuonana neYSY yekutengesa uye engineering zvikwata, isu takagadzirira iwe chero nguva yaunoda.

Nguva yekutumira: Jul-05-2022